TESTING

Design Validation Tests

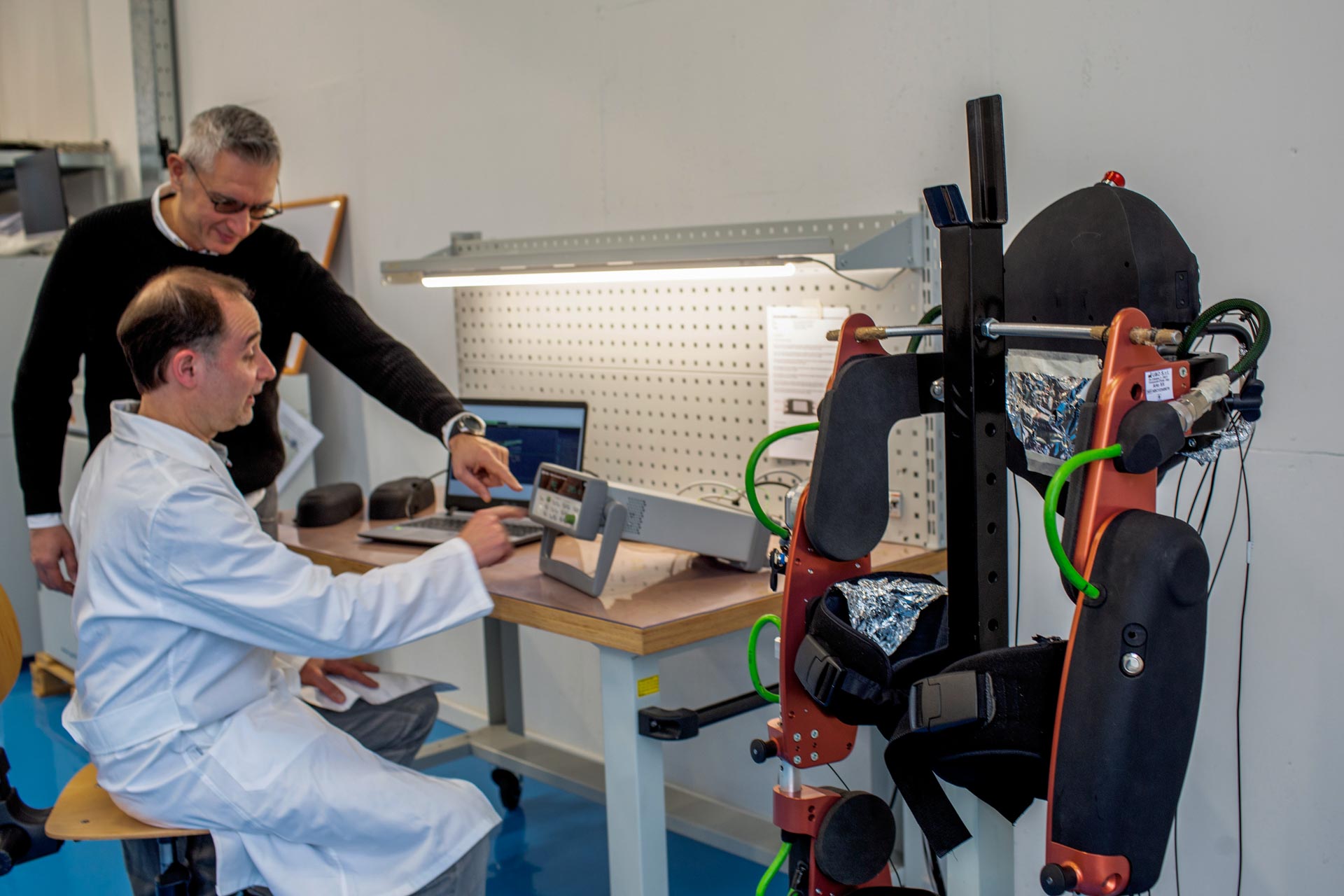

We mean with «DESIGN VALIDATION TESTS», all the safety testing activities put in place during the product development cycle, i.e., according toISO 9001 andISO 13485 managerial standards terminology, during«DESIGN VERIFICATION». Apparently looking like Partial Tests, the design validation tests, also and especially concernperformance tests, not only electric.

Also for this kind of activity, the manufacturer requires the intervention of an ISO 17025 accredited lab, generally because internally it has the necessary/calibrated equipment, or the specific expertise, or his needs to get them perfmormed by a third party to demonstrate to his customer the achievement of the goals of the commissioned project.

MEQUIPE, carries out DESIGN VALIDATION TESTS, accredited ISO 17025 to meet all the needs of manufacturers of:

- Medical devices

- Electrical and electronic equipment for domestic, industrial and similar use

- Luminaires

- Electronic equipment for information technology (IT)

- Audio visual (AV) Equipment

- Fire protection systems

Here is a list of the main tests:

- Performance Tests (in compliance with special norms)

- Measurement of contact and dispersion currents

- Measurement of the resistance of Earth conductors

- Flame test with needle

- Glow wire test

- Insulation resistance test

- Dielectric stiffness test

- Overtemperature measurements

- Fault tests

- Environmental tests

- IP tests

As for COMPLETE and PARTIAL TEST, also DESIGN VALIDATION TESTS, can be carried out both at our labsand at the customer’s production site.

Ask for a Quote

Scarica il Modulo per la richiesta di un preventivo